Our Services

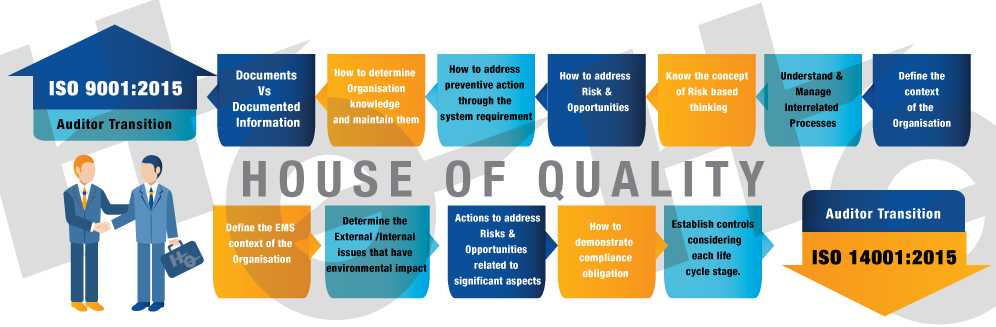

- ISO 9001 QMS

- ISO 14001 EMS

- OHSAS 18001 SMS

- ISO/TS 16949

- ISO 13485

- Supplementary Courses

- Value Added Courses

- Upgrade 2015

Range of Services

We also Deal With

ISO/TS 16949 QMS

ISO/TS 16949 QMS for Automotive devices

Course Outline

This course has been specially designed to provide an overview to companies who wish to develop and implement an effective quality system based on the requirements of the big three automotive manufacturers - Ford, Chrysler and General Motors.

This training will equip participants with a detailed interpretation, element by element, on the TS 16949 standard which includes both section I and section II requirements. Through understanding the basic requirements, the relevant interrelated documents like the SPC, FMEA, APQP, PPAP and MSA will also be discussed.

SPC Understand the concept and role of SPC in a Quality Management System.

FMEA Understand the methodology for developing and implementing FMEA in a company.

APQP Understand the concept of APQP and Control Plans including their application.

PPAP Overview of the procedures, reporting requirements and activities specified by the PPAP manual.

MSA Understand the measurement concept, application of MSA methodology for different types of measuring / test equipment and to evaluate MSA results.

Course Objectives

This course is specially prepared to provide participants with comprehensive understanding of:

• What is TS 16949 and the need for implementation

• Detail element by element interpretation

• Overview of interrelated documents like the FMEA, MSA, PPAP, APQP and SPC.

Course Content

• Interpretation of TS 16949 standard

• Planning and developing an effective quality system leading to certification

• Differences between ISO 9001 and TS 16949

• SPC - an introduction to common tools

• FMEA - implementing FMEA

• MSA - application of MSA methodology

• APQP/PPAP - APQP process and PPAP overview

Who should attend

All personnel who are actively involved in planning, developing and managing a quality system to meet the TS 16949 requirements.

All engineering, process or QA personnel who are involved with any aspect of process improvement, quality planning, PPAP submissions, development of FMEA, evaluation and assessment of measurement systems.

Course Objectives

This one day course is designed to develop an overall understanding and implementation knowledge on ISO/TS 16949

Upon completion of this course, participants will gain an in-depth knowledge on implementation which includes effective documentation for the requirements. Participants will be equiped with full knowledge & skills required to implement and maintain the system in accordance with ISO/TS 16949.

Course Content

• Brief introduction to ISO/TS 16949

• Implementation phases of ISO/TS 16949

• Effective documentation for the standard requirements

• APQP time chart implementation

• PPAP approval process

• Neccessity of FMEA, MSA, SPC implementation

Who should attend

Personnel who involve in management system, technical tools implementation, project management & engineering, quality management, production planning & control are encouraged to attend.

Course Objectives

This two days course is designed to develop the in-depth knowledge & skills on participants to audit the management system in accordance with ISO/TS 16949 using the automotive process approach.

Upon completion of this course, participants will understand the responsibilities of internal auditor and planning and scheduling for the audit.

Course Content

• Introduction to ISO/TS 16949

• Neccessity of ISO/TS 16949

• Understanding the ISO/TS 16949 requirements

• Auditing approach towards ISO/TS 16949

• System & Process auditing

• Verifying interrelated documents during the audit

• Case study & auditing exercise

Who should attend

Personnel who involve in management system, technical tools implementation, project management & engineering, quality management, production planning & control are encouraged to attend.